Schematic Checklist

Overview

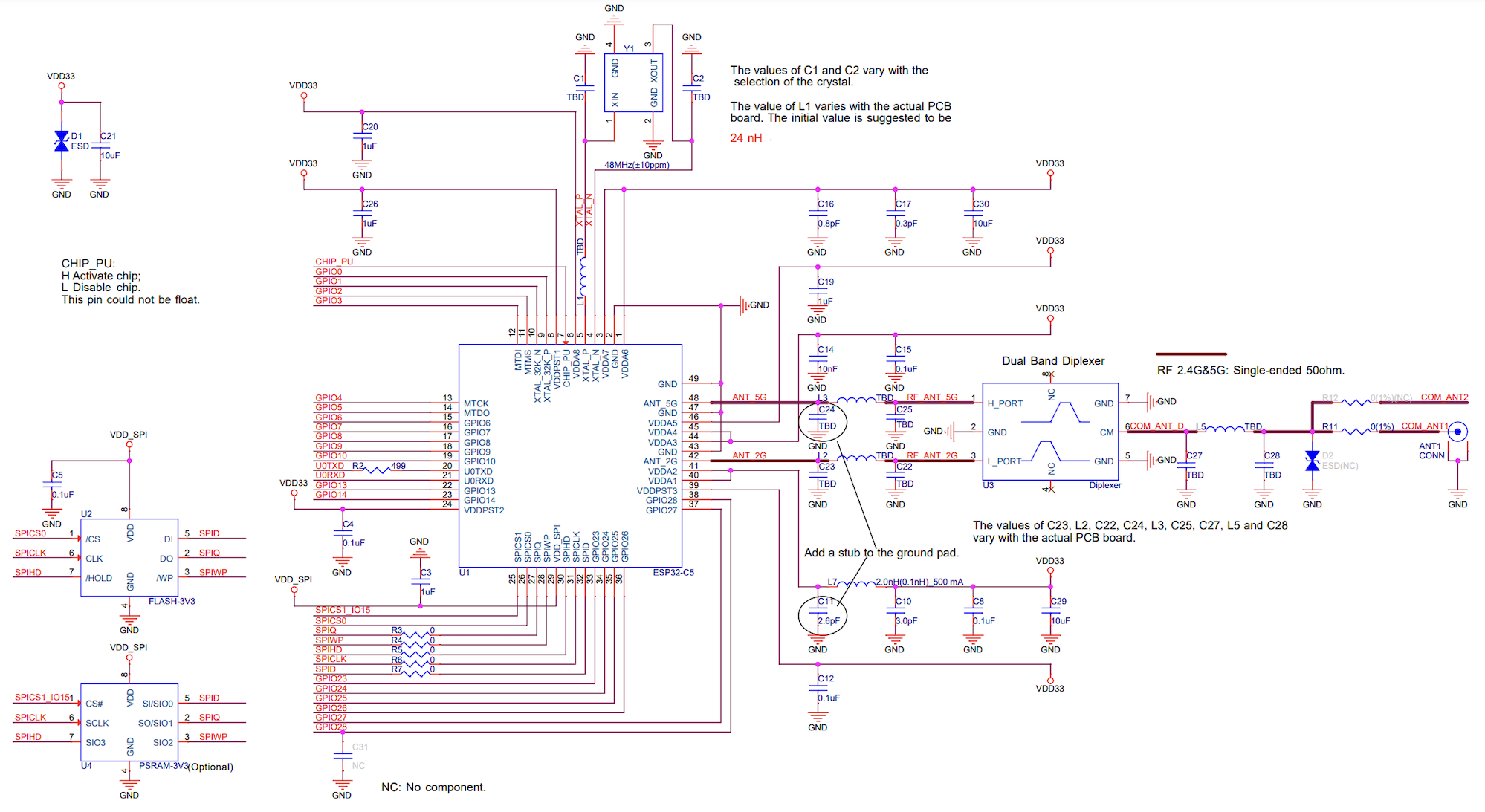

The integrated circuitry of ESP32-C5 requires only 30 electrical components (resistors, capacitors, and inductors) and a crystal, as well as an SPI flash. The high integration of ESP32-C5 allows for simple peripheral circuit design. This chapter details the schematic design of ESP32-C5.

The following figure shows a reference schematic design of ESP32-C5. It can be used as the basis of your schematic design.

ESP32-C5 Reference Schematic

Any basic ESP32-C5 circuit design may be broken down into the following major building blocks:

The rest of this chapter details the specifics of circuit design for each of these sections.

Power Supply

The general recommendations for power supply design are:

When using a single power supply, the recommended power supply voltage is 3.3 V and the output current is no less than 600 mA.

It is suggested to add an ESD protection diode and at least 10 μF capacitor at the power entrance.

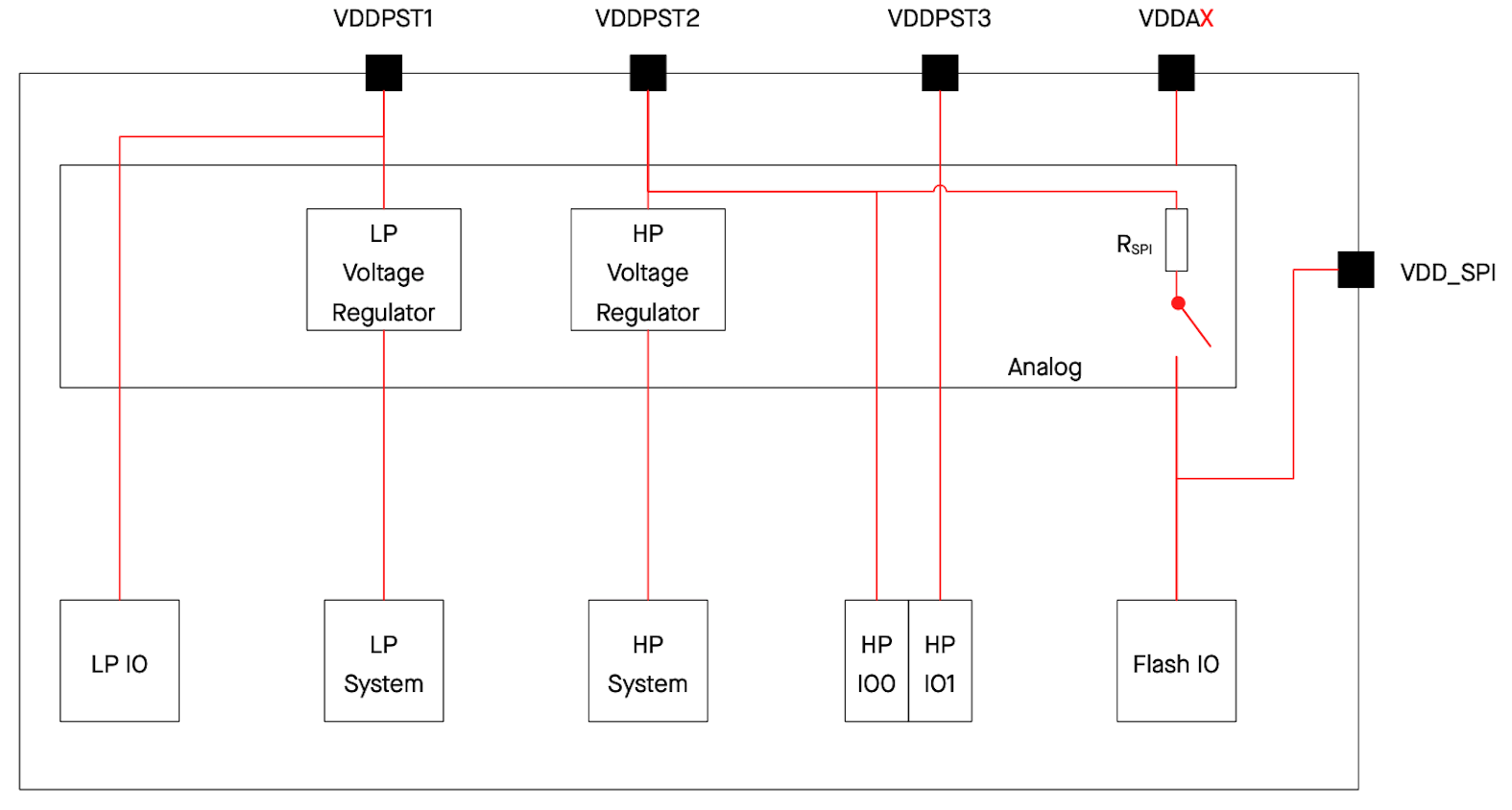

The power scheme is shown in Figure ESP32-C5 Power Scheme.

ESP32-C5 Power Scheme

More information about power supply pins can be found in ESP32-C5 Series Datasheet > Section Power Supply.

Digital Power Supply

ESP32-C5 has VDDPST1 (pin8), VDDPST2 (pin24), and VDDPST3 (pin39) as the digital power supply pin(s) working in a voltage range of 3.0 V ~ 3.6 V. It is recommended to add an extra 1 μF decoupling capacitor close to VDDPST1, and an extra 0.1 μF decoupling capacitor close to VDDPST2 and VDDPST3.

Pin VDD_SPI (pin29) can serve as the power supply for the external device at 3.3 V (typical value), provided by VDDPST2 via RSPI. Therefore, there will be some voltage drop from VDDPST2. When the VDD_SPI outputs 3.3 V, it is recommended that users add a 1 μF capacitor close to VDD_SPI.

VDD_SPI can be connected to and powered by an external power supply.

When not serving as a power supply pin, VDD_SPI can be used as a regular GPIO.

It is recommended to use the VDD_SPI to power the in-package or off-package flash/PSRAM.

Attention

When using VDD_SPI as the power supply pin for the in-package flash/PSRAM or external 3.3 V flash/PSRAM, considering the voltage drop mentioned above, VDDPST2 should be 3.0 V or above, so as to meet the requirements of flash/PSRAM’s working voltage.

Analog Power Supply

ESP32-C5’s VDDA1 to VDDA8 pins are the analog power supply pins, working at 3.0 V ~ 3.6 V.

For VDDA1, VDDA2, VDDA6, and VDDA7, when ESP32-C5 is transmitting signals, there may be a sudden increase in the current draw, causing power rail collapse. Therefore, it is highly recommended to add a 10 μF capacitor to the power rail, which can work in conjunction with the 1 μF capacitor(s) or other capacitors.

It is suggested to add an extra 10 μF capacitor at the power entrance. If the power entrance is close to VDDA1, VDDA2, VDDA6, and VDDA7, then two 10 μF capacitors can be merged into one.

Add an LC circuit on VDDA1 and VDDA2 power rails to suppress high-frequency harmonics. The inductor’s rated current is preferably 500 mA and above.

For the remaining capacitor circuits, please refer to ESP32-C5 Reference Schematic.

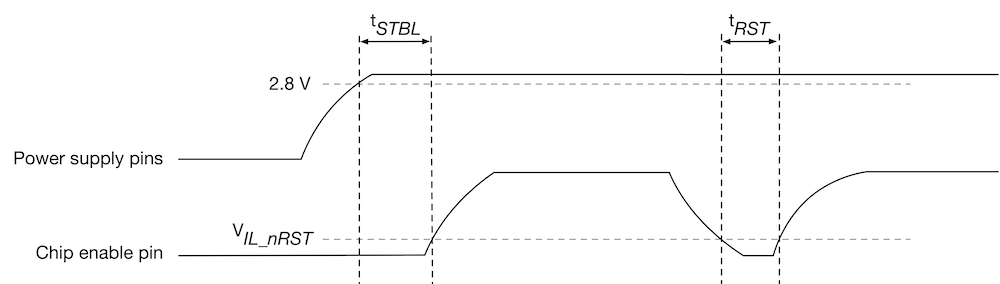

Chip Power-up and Reset Timing

ESP32-C5’s CHIP_PU pin can enable the chip when it is high and reset the chip when it is low.

When ESP32-C5 uses a 3.3 V system power supply, the power rails need some time to stabilize before CHIP_PU is pulled up and the chip is enabled. Therefore, CHIP_PU needs to be asserted high after the 3.3 V rails have been brought up.

To reset the chip, keep the reset voltage VIL_nRST in the range of (–0.3 ~ 0.25 × VDDPST1) V. To avoid reboots caused by external interferences, make the CHIP_PU trace as short as possible.

Figure ESP32-C5 Power-up and Reset Timing shows the power-up and reset timing of ESP32-C5.

ESP32-C5 Power-up and Reset Timing

Table Description of Timing Parameters for Power-up and Reset provides the specific timing requirements.

Parameter |

Description |

Minimum (µs) |

|---|---|---|

tSTBL |

Time reserved for the power rails to stabilize before the CHIP_PU pin is pulled high to activate the chip |

50 |

tRST |

Time reserved for CHIP_PU to stay below VIL_nRST to reset the chip |

50 |

Attention

CHIP_PU must not be left floating.

To ensure the correct power-up and reset timing, it is advised to add an RC delay circuit at the CHIP_PU pin. The recommended setting for the RC delay circuit is usually R = 10 kΩ and C = 1 μF. However, specific parameters should be adjusted based on the characteristics of the actual power supply and the power-up and reset timing of the chip.

If the user application has one of the following scenarios:

Slow power rise or fall, such as during battery charging.

Frequent power on/off operations.

Unstable power supply, such as in photovoltaic power generation.

Then, the RC circuit itself may not meet the timing requirements, resulting in the chip being unable to boot correctly. In this case, additional designs need to be added, such as:

Adding an external reset chip or a watchdog chip, typically with a threshold of around 3.0 V.

Implementing reset functionality through a button or the main controller.

Flash and PSRAM

ESP32-C5 requires in-package or off-package flash to store application firmware and data. In-package PSRAM or off-package PSRAM is optional.

In-Package Flash and PSRAM

The tables list the pin-to-pin mapping between the chip and in-package flash/PSRAM. Please note that the following chip pins can connect at most one flash and one PSRAM. That is to say, when there is only flash in the package, the pin occupied by flash can only connect PSRAM and cannot be used for other functions; when there is only PSRAM, the pin occupied by PSRAM can only connect flash; when there are both flash and PSRAM, the pin occupied cannot connect any more flash or PSRAM.

Pin Name |

Single SPI flash |

Dual SPI flash |

Quad SPI flash |

|---|---|---|---|

SPICLK |

CLK |

CLK |

CLK |

SPICS0 |

CS# |

CS# |

CS# |

SPID |

MOSI |

SIO0 |

SIO0 |

SPIQ |

MISO |

SIO1 |

SIO1 |

SPIWP |

WP# |

SIO2 |

|

SPIHD |

HOLD# |

SIO3 |

Pin Name |

Single SPI PSRAM |

Quad SPI PSRAM |

|---|---|---|

SPICLK |

CLK |

CLK |

SPICS1 |

CE# |

CE# |

SPID |

SI |

SIO0 |

SPIQ |

SO |

SIO1 |

SPIWP |

SIO2 |

|

SPIHD |

SIO3 |

Off-Package Flash and PSRAM

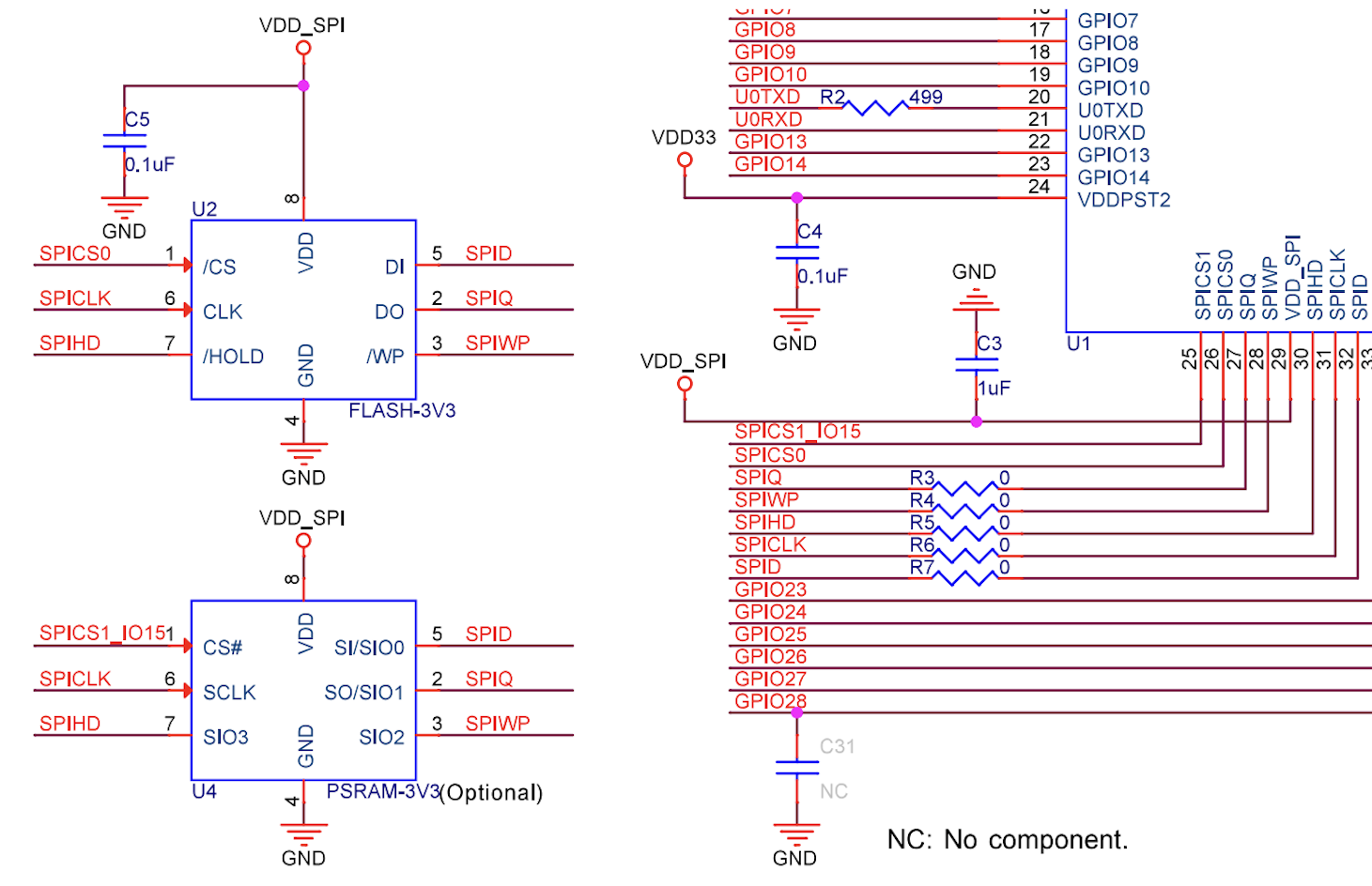

To reduce the risk of software compatibility issues, it is recommended to use flash and PSRAM models officially validated by Espressif. For detailed model selection, consult the sales or technical support team. It is recommended to add zero-ohm resistor footprints in series on the SPI communication lines as shown in Figure ESP32-C5 Schematic for External Flash/PSRAM. These footprints provide flexibility for future adjustments, such as tuning drive strength, mitigating RF interference, correcting signal timing, and reducing noise, if needed.

ESP32-C5 Schematic for External Flash/PSRAM

Clock Source

ESP32-C5 supports two external clock sources:

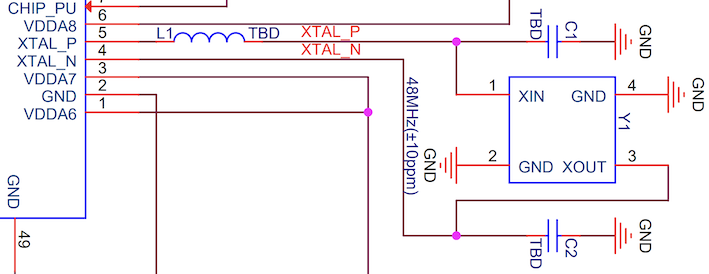

External Crystal Clock Source (Compulsory)

The ESP32-C5 firmware only supports 48 MHz crystal.

The circuit for the crystal is shown in Figure ESP32-C5 Schematic for External Crystal. Note that the accuracy of the selected crystal should be within ±10 ppm.

ESP32-C5 Schematic for External Crystal

Please add a series component on the XTAL_P clock trace. Initially, it is suggested to use an inductor of 24 nH to reduce the impact of high-frequency crystal harmonics on RF performance, and the value should be adjusted after an overall test.

The initial values of external capacitors C1 and C2 can be determined according to the formula:

where the value of CL (load capacitance) can be found in the crystal’s datasheet, and the value of Cstray refers to the PCB’s stray capacitance. The values of C1 and C2 need to be further adjusted after an overall test as below:

Select TX tone mode using the Certification and Test Tool.

Observe the 2.4 or 5 GHz signal with a radio communication analyzer or a spectrum analyzer and demodulate it to obtain the actual frequency offset.

Adjust the frequency offset to be within ±10 ppm (recommended) by adjusting the external load capacitance.

When the center frequency offset is positive, it means that the equivalent load capacitance is small, and the external load capacitance needs to be increased.

When the center frequency offset is negative, it means the equivalent load capacitance is large, and the external load capacitance needs to be reduced.

External load capacitance at the two sides are usually equal, but in special cases, they may have slightly different values.

Note

Defects in the manufacturing of crystal (for example, large frequency deviation of more than ±10 ppm, unstable performance within the operating temperature range, etc) may lead to the malfunction of ESP32-C5, resulting in a decrease of the RF performance.

It is recommended that the amplitude of the crystal is greater than 500 mV.

When Wi-Fi or Bluetooth connection fails, after ruling out software problems, you may follow the steps mentioned above to ensure that the frequency offset meets the requirements by adjusting capacitors at the two sides of the crystal.

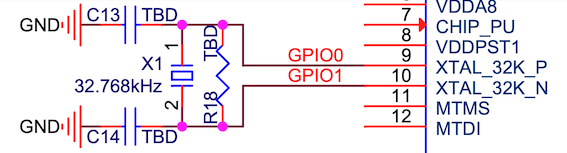

RTC Clock Source (Optional)

ESP32-C5 supports an external 32.768 kHz crystal to act as the RTC clock. The external RTC clock source enhances timing accuracy and consequently decreases average power consumption, without impacting functionality.

Figure ESP32-C5 Schematic for 32.768 kHz Crystal shows the schematic for the external 32.768 kHz crystal.

ESP32-C5 Schematic for 32.768 kHz Crystal

Please note the requirements for the 32.768 kHz crystal:

Equivalent series resistance (ESR) ≤ 70 kΩ.

Load capacitance at both ends should be configured according to the crystal’s specification.

The parallel resistor R is used for biasing the crystal circuit (5 MΩ < R ≤ 10 MΩ).

In general, you do not need to populate the resistor.

If the RTC clock source is not required, then the pins for the 32.768 kHz crystal can be used as GPIOs.

RF

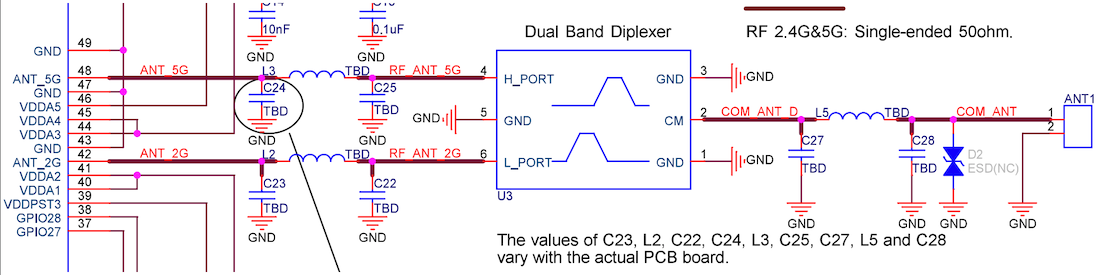

RF Circuit

ESP32-C5’s RF circuit is mainly composed of three parts, the RF traces on the PCB board, the chip matching circuit, the antenna and the antenna matching circuit. Each part should meet the following requirements:

For the RF traces on the PCB board, 50 Ω impedance control is required.

For the chip matching circuit, it must be placed close to the chip. A CLC structure is preferred.

The CLC structure is mainly used to adjust the impedance point and suppress harmonics, and a set of LC should be added separately for ANT_2G and ANT_5G RF interfaces.

The RF matching circuit is shown in Figure ESP32-C5 Schematic for RF Matching.

For the antenna and the antenna matching circuit, to ensure radiation performance, the antenna’s characteristic impedance must be around 50 Ω. Adding a CLC matching circuit near the antenna is recommended to adjust the antenna. However, if the available space is limited and the antenna impedance point can be guaranteed to be 50 Ω by simulation, then there is no need to add a matching circuit near the antenna.

The ANT_2G and ANT_5G RF interfaces can each be connected to a separate antenna (time-division multiplexing). In this case, it is recommended to add a CLCCL matching circuit on the 2G and 5G interfaces. Alternatively, both interfaces can be connected to a single antenna via a duplexer (LFD182G45DCHD481). The antenna must support dual-band operation.

It is recommended to include ESD protection devices for the antenna to mitigate electrostatic interference.

ESP32-C5 Schematic for RF Matching

RF Tuning

The RF matching parameters vary with the board, so the ones used in Espressif modules could not be applied directly. Follow the instructions below to do RF tuning.

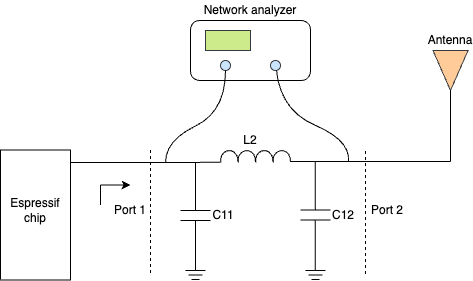

Figure ESP32-C5 RF Tuning Diagram shows the general process of RF tuning.

ESP32-C5 RF Tuning Diagram

In the matching circuit, define the port near the chip as Port 1 and the port near the antenna as Port 2. S11 describes the ratio of the signal power reflected back from Port 1 to the input signal power, the transmission performance is best if the matching impedance is conjugate to the chip impedance. S21 is used to describe the transmission loss of signal from Port 1 to Port 2. If S11 is close to the chip conjugate point (40 ~ 45)+j0 (2.4 GHz) or (50 ~ 65)+j0 (5 GHz) and S21 is less than -35 dB at 2nd and 3rd harmonics, the matching circuit can satisfy transmission requirements.

Connect the two ends of the matching circuit to the network analyzer, and test its signal reflection parameter S11 and transmission parameter S21. Adjust the values of the components in the circuit until S11 and S21 meet the requirements. If your PCB design of the chip strictly follows the PCB design stated in Chapter PCB Layout Design, you can refer to the value ranges in Table Recommended Value Ranges for Components to debug the matching circuit.

Reference Designator |

Recommended Value Range for 2.4 GHz |

Recommended Value Range for 5 GHz |

Serial No. |

C11 |

1.2 ~ 3.0 pF |

0.2 ~ 1.5 pF |

GRM0335C1H1RXBA01D |

L2 |

2.4 ~ 3.0 nH |

0 ~ 3 nH |

LQP03TN2NXB02D |

C12 |

1.2 ~ 3.0 pF |

0.2 ~ 1.5 pF |

GRM0335C1H1RXBA01D |

It is recommended to use RF matching components in the 0201 SMD package size. Please add a stub for the first capacitor in the 5 GHz matching circuit on the chip side.

Note

If RF function is not required, it is recommended not to initialize the RF stack in firmware. In this case, the RF pin can be left floating. However, if RF function is enabled, make sure an antenna is connected. Operation without an antenna may result in unstable behavior or potential damage to the RF circuit.

UART

ESP32-C5 includes 3 UART interfaces, UART0, UART1, and LP UART. U0TXD and U0RXD are GPIO11 and GPIO12 by default. Other signals can be mapped to any available GPIOs by software configurations.

LP UART pin configurations are shown in Table LP UART Pin Configurations.

Usually, UART0 is used as the serial port for download and log printing. For instructions on download over UART0, please refer to Section Download Guidelines. It is recommended to connect a 499 Ω series resistor to the U0TXD line to suppress harmonics.

If possible, use other UART interfaces as serial ports for communication. For these interfaces, it is suggested to add a series resistor to the TX line to suppress harmonics.

Signal |

Pin |

|---|---|

LP_UART_DTRN |

XTAL_32K_P |

LP_UART_DSRN |

XTAL_32K_N |

LP_UART_RTSN |

MTMS |

LP_UART_CTSN |

MTDI |

LP_UART_RXD |

MTCK |

LP_UART_TXD |

MTDO |

SPI

When using the SPI function, to improve EMC performance, add a series resistor (or ferrite bead) and a capacitor to ground on the SPI_CLK trace. If space allows, it is recommended to also add a series resistor and capacitor to ground on other SPI traces. Ensure that the RC/LC components are placed close to the pins of the chip or module.

Strapping Pins

At each startup or reset, a chip requires some initial configuration parameters, such as in which boot mode to load the chip, etc. These parameters are passed over via the strapping pins. After reset, the strapping pins work as normal function pins.

GPIO25, GPIO26, GPIO27, GPIO28, GPIO7, MTMS, and MTDI are strapping pins.

All the information about strapping pins is covered in ESP32-C5 Series Datasheet > Chapter Boot Configurations.

In this section, we will mainly cover the strapping pins related to boot mode.

After chip reset is released, the combination of GPIO26, GPIO27, and GPIO28 controls the boot mode. See Table Boot Mode Control.

Boot Mode |

GPIO26 |

GPIO27 |

GPIO28 |

|---|---|---|---|

Default Config |

– (Floating) |

1 (Pull-up) |

1 (Pull-up) |

SPI Boot (default) |

Any value |

Any value |

1 |

Joint Download Boot 0 1 |

Any value |

1 |

0 |

Joint Download Boot 1 2 |

0 |

0 |

0 |

- 1

Joint Download Boot 0 mode supports the following download methods:

USB-Serial-JTAG Download Boot

UART Download Boot

SPI Slave Download Boot (chip revision v0.1 only)

- 2

Joint Download Boot 1 mode supports the following download methods:

UART Download Boot

SDIO Download Boot

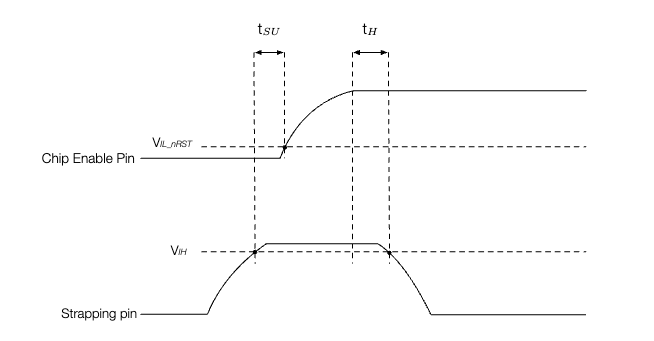

Signals applied to the strapping pins should have specific setup time and hold time. For more information, see Figure Setup and Hold Times for Strapping Pins and Table Description of Timing Parameters for Strapping Pins.

Parameter |

Description |

Minimum (ms) |

|---|---|---|

tSU |

Time reserved for the power rails to stabilize before the chip enable pin (CHIP_PU) is pulled high to activate the chip. |

0 |

tH |

Time reserved for the chip to read the strapping pin values after CHIP_PU is already high and before these pins start operating as regular IO pins. |

3 |

Attention

It is recommended to place a pull-up resistor at the GPIO28 pin.

It is recommended to leave space for a capacitor at GPIO28 for tuning purposes. Do not install the capacitor initially or use a large value, or the chip may enter download mode.

GPIO

The pins of ESP32-C5 can be configured via IO MUX or GPIO matrix. IO MUX provides the default pin configurations (see ESP32-C5 Series Datasheet > Appendix ESP32-C5 Consolidated Pin Overview), whereas the GPIO matrix is used to route signals from peripherals to GPIO pins. For more information about IO MUX and GPIO matrix, please refer to ESP32-C5 Technical Reference Manual > Chapter IO MUX and GPIO Matrix.

Some peripheral signals have already been routed to certain GPIO pins, while some can be routed to any available GPIO pins. For details, please refer to ESP32-C5 Series Datasheet > Section Peripherals.

When using GPIOs, please:

Pay attention to the states of strapping pins during power-up.

Pay attention to the default configurations of the GPIOs after reset. The default configurations can be found in the table below. It is recommended to add a pull-up or pull-down resistor to pins in the high-impedance state or enable the pull-up and pull-down during software initialization to avoid extra power consumption.

Avoid using the pins already occupied by flash.

Only LP GPIOs can be controlled in Deep-sleep mode, which are GPIO0 to GPIO6.

Pin No |

Pin Name |

Pin Providing Power |

At Reset |

After Reset |

|---|---|---|---|---|

9 |

XTAL_32K_P I |

VDDPST1 |

||

10 |

XTAL_32K_N |

VDDPST1 |

||

11 |

MTMS |

VDDPST1 |

IE |

IE |

12 |

MTDI |

VDDPST1 |

IE |

IE |

13 |

MTCK |

VDDPST1 |

IE, WPU |

|

14 |

MTDO |

VDDPST1 |

IE |

IE |

15 |

GPIO6 |

VDDPST1 |

IE |

IE |

16 |

GPIO7 |

VDDPST1 |

IE |

IE |

17 |

GPIO8 |

VDDPST1 |

IE |

|

18 |

GPIO9 |

VDDPST1 |

IE |

|

19 |

GPIO10 |

VDDPST1 |

IE |

|

20 |

U0TXD |

VDDPST1 |

WPU |

|

21 |

U0RXD |

VDDPST1 |

IE, WPU |

|

22 |

GPIO13 |

VDDPST2 |

IE |

|

23 |

GPIO14 |

VDDPST2 |

USB_PU |

IE, USB_PU |

25 |

SPICS1 |

VDD_SPI |

WPU |

IE, WPU |

26 |

SPICS0 |

VDD_SPI |

WPU |

IE, WPU |

27 |

SPIQ |

VDD_SPI |

WPU |

IE, WPU |

28 |

SPIWP |

VDD_SPI |

WPU |

IE, WPU |

29 |

VDD_SPI |

|||

30 |

SPIHD |

VDD_SPI |

WPU |

IE, WPU |

31 |

SPICLK |

VDD_SPI |

WPU |

IE, WPU |

32 |

SPID |

VDD_SPI |

WPU |

IE, WPU |

33 |

GPIO23 |

VDDPST3 |

IE |

|

34 |

GPIO24 |

VDDPST3 |

IE |

|

35 |

GPIO25 |

VDDPST3 |

IE |

IE |

36 |

GPIO26 |

VDDPST3 |

IE |

IE |

37 |

GPIO27 |

VDDPST3 |

IE, WPU |

IE, WPU |

38 |

GPIO28 |

VDDPST3 |

IE, WPU |

IE, WPU |

IE – input enabled

WPU – internal weak pull-up resistor enabled

ADC

Please add a 0.1 μF filter capacitor between ESP pins and ground when using the ADC function to improve accuracy.

ADC functions are shown in the table below.

Pin No |

IO Pin Name |

ADC Function |

|---|---|---|

10 |

GPIO1 |

ADC1_CH0 |

11 |

GPIO2 |

ADC1_CH1 |

12 |

GPIO3 |

ADC1_CH2 |

13 |

GPIO4 |

ADC1_CH3 |

14 |

GPIO5 |

ADC1_CH4 |

15 |

GPIO6 |

ADC1_CH5 |

SDIO

ESP32-C5 series has only one SDIO slave controller that conforms to the industry-standard SDIO Specification Version 2.0. SDIO should be connected to specific GPIOs, namely SDIO_CMD/GPIO10, SDIO_CLK/GPIO9, SDIO_DATA0/GPIO8, SDIO_DATA1/GPIO7, SDIO_DATA2/GPIO14, and SDIO_DATA3/GPIO13. Please add a pull-up resistor to these GPIOs, and preferably reserve a series resistor on each trace.

Note

This peripheral is supported by the chip revision v1.0, but not by v0.1.

USB

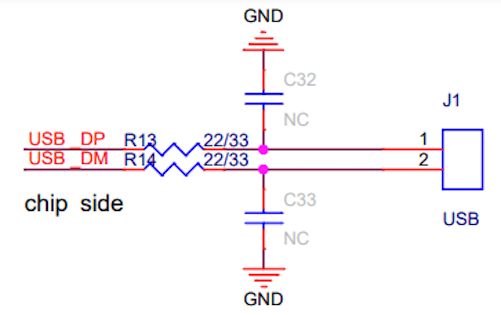

ESP32-C5 integrates a USB Serial/JTAG controller that supports USB 2.0 full-speed device.

GPIO13 and GPIO14 can be used as D- and D + of USB respectively. It is recommended to populate 22/33 ohm series resistors between the mentioned pins and the USB connector. Also, reserve a footprint for a capacitor to ground on each trace. Note that both components should be placed close to the chip.

The USB RC circuit is shown in Figure ESP32-C5 USB RC Schematic.

ESP32-C5 USB RC Schematic

Note that upon power-up, the USB_D+ signal will fluctuate between high and low states. The high-level signal is relatively strong and requires a robust pull-down resistor to drive it low. Therefore, if you need a stable initial state, adding an external pull-up resistor is recommended to ensure a consistent high-level output voltage at startup.

ESP32-C5 also supports download functions and log message printing via USB. For details please refer to Section Download Guidelines.