ESP Sensorless BLDC Control Components

This guide includes the following content:

Table of Contents

The esp_sensorless_bldc_control component is a sensorless BLDC square wave control library based on the ESP32 series chips. It currently supports the following features:

Zero-crossing detection based on ADC sampling

Zero-crossing detection supported by comparators

Rotor initial phase detection based on the pulse method

Stall protection

This article mainly explains how to use the esp_sensorless_bldc_control component for brushless motor development and does not cover the principles. For more information on the principles, please refer to:

Overview of Bldc Motor Control Overview of Brushless Motor Control

Sensorless Square Wave Motor Control Based on ADC Sampling Zero-crossing Detection Based on ADC Sampling

Sensorless Square Wave Motor Control Based on Comparator Detection Zero-crossing Detection Based on Comparators

The sensorless square wave control process can be mainly divided into the following parts:

INJECT: Injection phase, obtaining the initial phase through high-frequency voltage pulses

INJECTALIGNMENT: Alignment phase, fixing the rotor to the initial phase

ALIGNMENTDRAG: Drag phase, rotating the rotor through six-step commutation

DRAGCLOSED_LOOP: Sensorless closed-loop control, commuting by detecting back EMF zero-crossing points

CLOSED_LOOPBLOCKED: Motor stall

BLOCKEDSTOP: Motor stop

STOPFAULT: Motor fault

FAULT

Next, the specific processes of each part and the parameters to be noted will be introduced.

INJECT

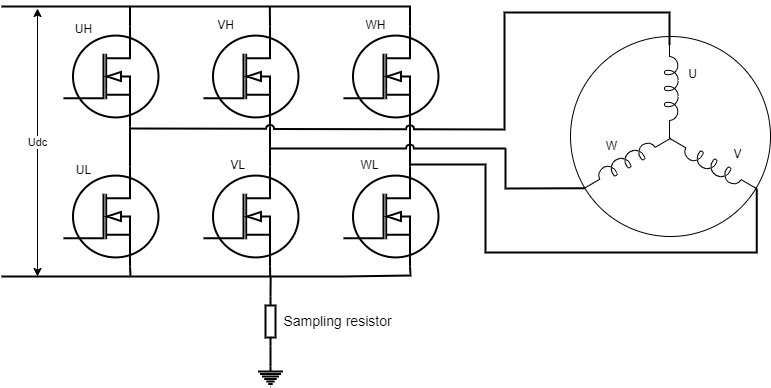

The initial phase of the motor is obtained through pulse injection, and the bus current is collected at the low end of the inverter circuit. As shown in the figure below:

BLDC Bus Current Collection

Note

Since the current cannot be collected directly, a sampling resistor is used to convert the current into voltage. Note that the voltage needs to be converted to a range that the ESP32 ADC can collect. Please refer to: ESP32 ADC

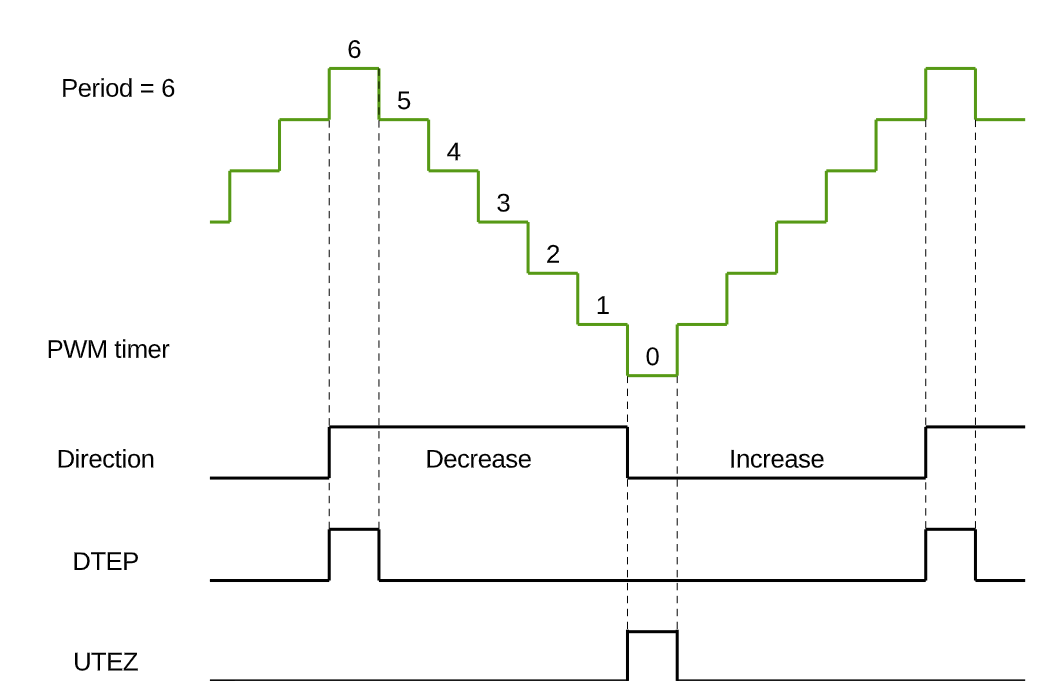

Since the current only exists when both the upper and lower tubes are conducting, ADC sampling needs to be performed when the upper tube is conducting. Configure MCPWM in rising and falling mode and sample when the counter reaches the peak to accurately collect the bus voltage.

MCPWM Rising and Falling Mode

Note

The LEDC driver does not support callback triggering at high levels, so the INJECT mode cannot be used with the LEDC driving method.

INJECT_ENABLE is set to 1 to enable INJECT mode, otherwise, it is disabled. The default is 0. The PWM generation mode must be MCPWM.

INJECT_DUTY is the injected voltage size, generally using high duty cycle injection.

CHARGE_TIME is the inductance charging time and pulse injection time, which affects the accuracy of initial phase detection. If this value is too small, the collected ADC value will be 0; if it is too large, the ADC value will be too high. Manually rotate the motor, and it is best to obtain stable phases 1-6 in one turn without errors phases 0 and 7.

ALIGNMENT

To ensure the brushless motor can start normally, it is necessary to determine the position of the rotor when it is stationary. In practical applications, this is done by energizing a set of windings for a certain period, fixing the rotor in a specific phase, and preparing for subsequent forced commutation.

ALIGNMENTNMS Alignment time, if too long, it will overcurrent. If too short, the rotor may not be aligned to the correct phase.

ALIGNMENTDUTY Alignment force.

DRAG

The rotor is dragged through six-step commutation, using a boost and frequency increase method. Gradually increase the voltage and commutation frequency to give the motor an initial speed with a significant back EMF. The motor should drag smoothly without noise or stuttering. The drag time does not need to be too long.

RAMP_TIM_STA Initial delay time for dragging.

RAMP_TIM_END Minimum delay time for dragging.

RAMP_TIM_STEP Step increment for drag time.

RAMP_DUTY_STA Initial duty cycle for dragging.

RAMP_DUTY_END Maximum duty cycle for dragging.

RAMP_DUTY_INC Step increment for the duty cycle.

Note

The strong drag parameters need to be tuned in the motor’s working environment, and the no-load parameters may not apply to the loaded condition.

CLOSED_LOOP

Zero-crossing Detection Based on ADC Sampling

ADC sampling detects the zero-crossing point by collecting the floating phase voltage and motor power supply voltage, and sampling must be performed when the upper tube is conducting.

Note

ADC zero-crossing detection must use MCPWM as the driver.

ENTER_CLOSE_TIME Sets the time to enter the closed loop. By default, the closed loop control can be entered after a period of strong drag.

ZERO_REPEAT_TIME The zero-crossing point is considered valid after being detected continuously N times.

AVOID_CONTINUE_CURRENT_TIME After commutation, there will be an impact of continuous current. Delay detection to avoid continuous current.

Zero-crossing Detection Based on Comparator

Comparator zero-crossing detection compares the floating phase back EMF with the bus voltage using hardware comparators. The zero-crossing signal is detected by the GPIO pin. Due to many noise points in the actual process, multiple detections are needed to confirm the zero-crossing point.

ZERO_STABLE_FLAG_CNT Enter sensorless control after multiple stable zero-crossing signals are detected.

ZERO_CROSS_DETECTION_ACCURACY Continuous detection of the same signal N times is considered a stable signal. 0xFF means 8 times, 0XFFFF means 16 times. The current maximum supported filtering times are 0xFFFFFFFF. If it still cannot enter the closed loop state, check for hardware issues.

Note

Hardware troubleshooting directions mainly include checking whether the filter capacitors for the three-phase terminal voltage and comparator output are set reasonably.

Advance Commutation

The zero-crossing signal generally arrives 30° before commutation. Once the zero-crossing signal is detected, a 30° delay is required. However, during motor rotation, due to variable electrical cycles, software filtering, and delays, a slight compensation for the commutation time is necessary.

ZERO_CROSS_ADVANCE Advance commutation time, the advance angle is 180 / ZERO_CROSS_ADVANCE, default is 6.

Note

The commutation angle is not better the earlier it is. Use an oscilloscope to observe whether the calculated commutation angle matches the actual commutation angle.

Stall Protection

If the motor does not commutate for a long time, it is considered stalled. At this point, the motor stops running and enters stall protection status.

Speed Control

The speed is controlled by PID to achieve the set speed.

SPEED_KP P value of speed control.

SPEED_KI I value of speed control.

SPEED_KD D value of speed control.

SPEED_MIN_INTEGRAL Minimum integral value of speed control.

SPEED_MAX_INTEGRAL Maximum integral value of speed control.

SPEED_MIN_OUTPUT Minimum output value of speed control.

SPEED_MAX_OUTPUT Maximum output value of speed control, not exceeding the maximum duty cycle.

SPEED_CAL_TYPE Position PID or Incremental PID.

SPEED_MAX_RPM Maximum RPM.

SPEED_MIN_RPM Minimum RPM.

MAX_SPEED_MEASUREMENT_FACTOR To avoid erroneous speed detection, if the detected speed exceeds this set factor, it is considered an erroneous speed detection.

API Reference

Header File

Functions

-

ESP_EVENT_DECLARE_BASE(BLDC_CONTROL_EVENT)

using esp_event_handler_register() to register BLDC_CONTROL_EVENT

esp event name

-

esp_err_t bldc_control_init(bldc_control_handle_t *handle, bldc_control_config_t *config)

init bldc control

- Parameters

handle – pointer to bldc control handle

config – pointer to bldc control config

- Returns

ESP_ERR_INVALID_ARG if handle or config is NULL ESP_ERR_NO_MEM if memory allocation failed ESP_OK on success ESP_FAIL on other errors

-

esp_err_t bldc_control_deinit(bldc_control_handle_t *handle)

deinit bldc control

- Parameters

handle – pointer to bldc control handle ESP_ERR_INVALID_ARG if handle or config is NULL ESP_OK on success ESP_FAIL on other errors

-

esp_err_t bldc_control_start(bldc_control_handle_t *handle, uint32_t expect_speed_rpm)

motor start

- Parameters

handle – pointer to bldc control handle

expect_speed_rpm – expect speed in rpm. This parameter does not work in case of open-loop control

- Returns

ESP_OK on success

-

esp_err_t bldc_control_stop(bldc_control_handle_t *handle)

motor stop

- Parameters

handle – pointer to bldc control handle

- Returns

ESP_FAIL if motor stop failed ESP_OK on success

-

dir_enum_t bldc_control_get_dir(bldc_control_handle_t *handle)

get current motor direction

- Parameters

handle – pointer to bldc control handle

- Returns

dir_enum_t current motor direction

-

esp_err_t bldc_control_set_dir(bldc_control_handle_t *handle, dir_enum_t dir)

set motor direction

- Parameters

handle – pointer to bldc control handle

dir – motor direction

- Returns

ESP_OK on success

-

int bldc_control_get_duty(bldc_control_handle_t *handle)

get current motor pwm duty

- Parameters

handle – pointer to bldc control handle

- Returns

int current motor pwm duty

-

esp_err_t bldc_control_set_duty(bldc_control_handle_t *handle, uint16_t duty)

set motor pwm duty, Closed-loop speed control without calls

- Parameters

handle – pointer to bldc control handle

duty – motor pwm duty

- Returns

ESP_OK on success

-

int bldc_control_get_speed_rpm(bldc_control_handle_t *handle)

get current RPM

- Parameters

handle – pointer to bldc control handle

- Returns

int current RPM

-

esp_err_t bldc_control_set_speed_rpm(bldc_control_handle_t *handle, int speed_rpm)

set motor RPM

- Parameters

handle – pointer to bldc control handle

speed_rpm – motor RPM

- Returns

ESP_OK on success

Structures

-

struct bldc_debug_config_t

Debug configuration, when activated, will periodically invoke the debug_operation.

-

struct bldc_control_config_t

BLDC Control Configuration.

Public Members

-

speed_mode_t speed_mode

Speed Mode

-

control_mode_t control_mode

Control Mode

-

alignment_mode_t alignment_mode

Alignment Mode

-

bldc_six_step_config_t six_step_config

six-step phase change config

-

bldc_zero_cross_comparer_config_t zero_cross_comparer_config

Comparator detects zero crossing config

-

bldc_debug_config_t debug_config

debug config

-

speed_mode_t speed_mode

Type Definitions

-

typedef void *bldc_control_handle_t

bldc control handle

Enumerations

-

enum bldc_control_event_t

Values:

-

enumerator BLDC_CONTROL_START

BLDC control start event

-

enumerator BLDC_CONTROL_ALIGNMENT

BLDC control alignment event

-

enumerator BLDC_CONTROL_DRAG

BLDC control drag event

-

enumerator BLDC_CONTROL_STOP

BLDC control stop event

-

enumerator BLDC_CONTROL_CLOSED_LOOP

BLDC control closed loop event

-

enumerator BLDC_CONTROL_BLOCKED

BLDC control blocked event

-

enumerator BLDC_CONTROL_START

Header File

Macros

-

BLDC_LEDC

-

BLDC_MCPWM

-

PWM_MODE

Configure the generation of PWM.

Configure the generation of PWM.

-

MCPWM_CLK_SRC

MCPWM Settings.

Number of count ticks within a period time_us = 1,000,000 / MCPWM_CLK_SRC

-

MCPWM_PERIOD

pwm_cycle_us = 1,000,000 / MCPWM_CLK_SRC * MCPWM_PERIOD

-

FREQ_HZ

LEDC Settings.

-

DUTY_RES

Set duty resolution to 11 bits

-

ALARM_COUNT_US

No changes should be made here.

-

DUTY_MAX

-

PWM_DUTYCYCLE_05

-

PWM_DUTYCYCLE_10

-

PWM_DUTYCYCLE_15

-

PWM_DUTYCYCLE_20

-

PWM_DUTYCYCLE_25

-

PWM_DUTYCYCLE_30

-

PWM_DUTYCYCLE_40

-

PWM_DUTYCYCLE_50

-

PWM_DUTYCYCLE_60

-

PWM_DUTYCYCLE_80

-

PWM_DUTYCYCLE_90

-

PWM_DUTYCYCLE_100

-

INJECT_ENABLE

Pulse injection-related parameters.

Note

Used to detect the initial phase of the motor; MCPWM peripheral support is necessary. Whether to enable pulse injection.

-

INJECT_DUTY

Injected torque.

-

CHARGE_TIME

Capacitor charging and injection time.

-

ALIGNMENTNMS

Parameters related to motor alignment. Used to lock the motor in a specific phase before strong dragging.

Duration of alignment, too short may not reach the position, too long may cause the motor to overheat.

-

ALIGNMENTDUTY

alignment torque.

-

RAMP_TIM_STA

Setting parameters for strong dragging. The principle of strong dragging is to increase the control frequency and intensity.

Note

If the control cycle speeds up, corresponding reductions should be made to the RAMP_TIM_STA, RAMP_TIM_END, RAMP_TIM_STEP The start step time for climbing. A smaller value results in faster startup but may lead to overcurrent issues.

-

RAMP_TIM_END

The end step time for climbing, adjusted based on the load. If loaded, this value should be relatively larger.

-

RAMP_TIM_STEP

Decremental increment for climbing step time—adjusted in accordance with RAMP_TIM_STA.

-

RAMP_DUTY_STA

The starting torque for climbing.

-

RAMP_DUTY_END

The ending torque for climbing.

-

RAMP_DUTY_INC

The incremental torque step for climbing—too small a value may result in failure to start, while too large a value may lead to overcurrent issues.

-

ENTER_CLOSE_TIME

ADC parameters for zero-crossing detection; please do not delete if not in use.

Enter the closed-loop state delay times.

-

ZERO_REPEAT_TIME

Change phase after detecting zero-crossing signals continuously for several times.

-

AVOID_CONTINUE_CURRENT_TIME

Avoiding Continuous Current

-

ZERO_STABLE_FLAG_CNT

Comparator parameters for zero-crossing detection; please do not delete if not in use.

After stable detection for multiple revolutions, it is considered to enter a sensorless state.

-

ZERO_CROSS_DETECTION_ACCURACY

Count a valid comparator value every consecutive detection for how many times.

-

ZERO_CROSS_ADVANCE

Common parameter for compensated commutation time calculation.

Advance switching at zero-crossing, switching angle = 180°/ZERO_CROSS_ADVANCE. angle compensation should be provided. >= 6

-

POLE_PAIR

Motor parameter settings.

Number of pole pairs in the motor.

-

BASE_VOLTAGE

Rated voltage.

-

BASE_SPEED

Rated speed unit: rpm.

-

SPEED_KP

Closed-loop PID parameters for speed.

P

-

SPEED_KI

I

-

SPEED_KD

D

-

SPEED_MIN_INTEGRAL

Minimum integral saturation limit.

-

SPEED_MAX_INTEGRAL

Maximum integral saturation limit.

-

SPEED_MIN_OUTPUT

Minimum PWM duty cycle output.

-

SPEED_MAX_OUTPUT

Maximum PWM duty cycle output.

-

SPEED_CAL_TYPE

0 Incremental 1 Positional

-

SPEED_MAX_RPM

Speed parameter settings.

Maximum speed.

-

SPEED_MIN_RPM

Minimum speed.

-

MAX_SPEED_MEASUREMENT_FACTOR

Supports a measured speed range from 0 to 1.2 times SpeedMAX. Large values could prevent proper filtering of incorrect data.